Industrial cooling

- visionary systems from Fenagy

Browse our industrial cooling systems

C-RANGE CHILLERS

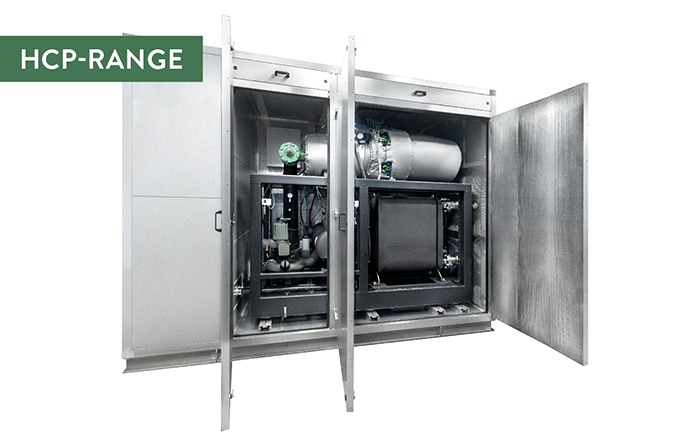

HCP-RANGE CHILLERS

Modern & high-performing cooling systems for industrial applications

Cooling solutions for food processing

Cooling solutions for food processing

Cooling of industrial cold storage

Cooling for the pharmaceutical industry

Dairy cooling solutions

Why choose a cooling solution from Fenagy?

Our chillers offer a variety of advantages for the customer. Some of the most prominent benefits of our cooling solutions are that they:

Use only natural refrigerants (Propane, CO2, & Isobutane)

Can be tailored to customer-specific setups and conditions

Can be delivered with an industrial walk-in enclosure

Have a state-of-the-art Siemens PLC controlling and monitoring system

Are manufactured at our own plant in Denmark, which ensures consistent high quality

Do you need a modern and flexible cooling system?

At Fenagy, we have extensive experience tailoring systems to the specific needs and specifications of our clients. Supporting your daily operations and needs is the foremost priority for us, when we produce our systems. Thus, we always strive to better our products by integrating the newest technology and developments in order to continue delivering products of the very highest standard.

Hence, if you have specific requirements for your new cooling system, we can almost certainly help you get the exact solution that matches your needs. You can always contact us for a talk about your needs and what we can offer to accommodate them.

Combined solution for simultaneous cooling & heating

Outside of our standalone cooling/chiller units, we also produce innovative units that combine both heating and cooling capabilities for either simultaneous or individual use. Meaning that you can either use both capabilities at once or you can use one of the heating or cooling functions on its own, depending on the needs and demands of the specific circumstances.

With one of our combined solutions, the heat that is removed is then repurposed for heating rather than simply wasting the available resource. Not only is this financially beneficial but it can also aid in furthering a company’s sustainability goals.

Technical specifications for our chillers

Industrial cooling for a variety of industries

Cooling and heating are used extensively in almost all industries imaginable. However, in many of these, smarter solutions could be employed to the benefit of all parties involved, but not least the companies attempting to turn a profit.

For instance, in datacenters, logistics hubs, food processing facilities, and a plethora of other places where both cooling and heating are needed, one of our combined solutions can be employed to great benefit. We have examples of how we tailored and employed a solution to improve resource usage across a variety of industries. But don’t just take our word for it, see for yourself!

Key features of Fenagy chillers for cooling

DX plate heat exchanger evaporator (chiller)

Patented ejector technology for optimisation of capacity and COP

Fast start and stop for balancing the electrical grid

Air-cooled gas cooler

Heat recovery with plate heat exchanger

Industrial design with stainless steel piping

PLC control of the entire system

Water pump, energy meter and various valves can be integrated on the rack

High-capacity screw compressor technology

Available for heat pump and chiller applications (HCP)

Industrial heat pump systems with natural refrigerants

-

APPLICATIONS: District heating, heat networks, industrial processes, food industry, green houses, data centres, logistics centres, offices, hospitals and HVAC in general

Natural refrigerant with a wide temperature range

Non-toxic and non-flammable

Excellent choice for air-sourced heat pumps for direct use in the energy collectors and with high delta T on the heat sink side

Optimal for medium-temperature water-sourced heat pumps, chillers and combined heating and cooling applications

Medium-high temperature level on heat sink (up to 85°C supply temp) with high delta T on the heat sink (dT: 30-40K)

-

APPLICATIONS: Heat networks, biogas, PtX, geothermal, carbon capture, CO₂ heat pump sub-cooler, industrial processes and food industry

High-temperature natural refrigerant

Suitable for water-sourced heat pumps and chillers

Can be used in a wide temperature range on both the heat source and heat sink sides

Robust operation under various operating conditions

Use of efficient screw compressors and high COP of the cycle

High temperature level on heat source (up to 40°C evap. temp)

High temperature level on heat sink (up to 95°C supply temp) and ideal with low delta T on heat sink - serial coupling on water side at higher delta T

-

APPLICATIONS: Heat networks, industrial processes, food industry, data centres, offices, hospitals and HVAC in general

Low-temperature natural refrigerant

Suitable for lower temperature water-sourced heat pumps and chillers

Low temperature level on heat source (down to -30 °C evap. temp)

Medium temperature level on heat sink (up to 75 °C supply temp)

Ideal with low delta T on sink and heat source

High refrigeration capacity ensures compact solutions with small footprint

Can be combined with isobutane in serial hydraulic couplings

Do you want to know more?

If you have any questions or considerations, don’t hesitate to reach out. We are always happy to answer any inquiry you might have.