HCI-RANGE - heat pumps, chillers and combined systems

The Fenagy HCI-range reaches capacities from 500 kW to 6,000 kW heat per system. The systems can be used for heat pump, chiller

and combined water-water operation. The entire range is designed to deliver optimal performance in accordance with customer-specific operation needs. The HCI-range is only available as water-to-water systems, thereby ensuring a small refrigerant charge.

The HCI-range uses the natural refrigerant isobutane and can reach supply temperatures up to 95°C, regardless of the return temperature.

The HCI-range is typically used for high-temperature heat pump applications, heat pumps for the energy sector (PtX, geothermal,

biogas, CCSU), industrial processes, as mechanical sub-cooler and as booster in district heating systems. The systems can also be used

as water-sourced heat pumps for district heating or heat networks and for normal water-cooled chiller applications.

APPLICATIONS

High-temperature heat pumps

Heat pumps for the energy sector

(PtX, geothermal, biogas, CCSU)

Industrial processes

Mechanical sub-cooler

Booster in district heating systems

Easy installation with enclosure

The HCI-range systems are always delivered in a reach-in enclosure, which is suitable for both in- and outdoor installation.

The enclosure is constantly ventilated with an EX-fan, which ensures negative pressure and maintains the right temperature in the cabinet.

The enclosure has insulated walls with sound dampening panels.

Control systems

The complete range uses a standard Siemens PLC controller, and Fenagy has developed its own PLC algorithms for the most essential functions to ensure optimal control and monitoring. Our PLC solutions can communicate with most of the platforms the customer will need to communicate with. The onboard HMI panel offers direct monitoring of the system and its operating conditions. Furthermore, our PLC solutions support several communication protocols and can integrate with the overall SCADA system.

For all systems, Fenagy aspires to minimise start-up and shutdown times, enabling the system to help balance the electrical grid in a future with an increasing demand for such functions. Last, but not least, the system can deliver high supply temperatures, and Fenagy is continuously pushing the boundaries with new functions and features in the PLC development.

Technical specifications

& key features

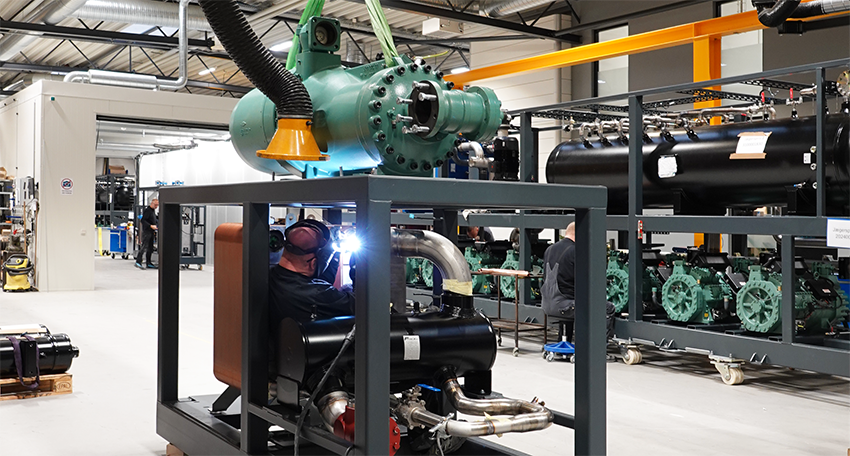

High-capacity screw compressor technology

Unique for applications with high temperature on the heat source

Available for heat pump and chiller applications

Fast start and stop for balancing the electrical grid

Industrial design with stainless steel piping

PLC control of the entire system

We only use natural refrigerants

R744 - CO₂

APPLICATIONS: District heating, heat networks, industrial processes, food industry, green houses, data centres, logistics centres, offices, hospitals and HVAC in general

Natural refrigerant with a wide temperature range

Non-toxic and non-flammable

Excellent choice for air-sourced heat pumps for direct use in the energy collectors and with high delta T on the heat sink side

Optimal for medium-temperature water-sourced heat pumps, chillers and combined heating and cooling applications

Medium-high temperature level on heat sink (up to 85°C supply temp) with high delta T on the heat sink (dT: 30-40K)

R600a - Isobutane

APPLICATIONS: Heat networks, Biogas, PtX, geothermal, carbon capture, CO₂ heat pump sub-cooler, industrial processes and food industry

High-temperature natural refrigerant

Suitable for water-sourced heat pumps and chillers

Can be used in a wide temperature range on both the heat source and heat sink sides

Robust operation under various operating conditions

Use of efficient screw compressors and high COP of the cycle

High temperature level on heat source (up to 40°C evap. temp)

High temperature level on heat sink (up to 95°C supply temp) and ideal with low delta T on heat sink - serial coupling on water side at higher delta T

R290 - Propane

APPLICATIONS: Heat networks, industrial processes, food industry, data centres, offices, hospitals and HVAC in general

Low-temperature natural refrigerant

Suitable for lower temperature water-sourced heat pumps and chillers

Low temperature level on heat source (down to -30 °C evap. temp)

Medium temperature level on heat sink (up to 75 °C supply temp)

Ideal with low delta T on sink and heat source

High refrigeration capacity ensures compact solutions with small footprint

Can be combined with isobutane in serial hydraulic couplings

The most visionary

hydrocarbon

systems in the world